Why PROPINK® Insulation?

High Performance Insulation For High Performance Building

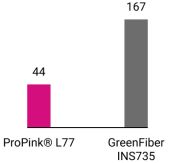

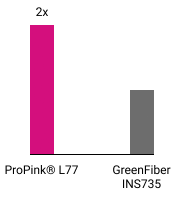

Owens Corning ProPink® L77 Loosefill Insulation offers outstanding coverage, fast application and exceptional R-value per square inch when compared to other fiberglass insulation products. Its simplicity and consistency allows installers to use one product for walls, attics, cathedral ceilings and floors. It’s also one of the few insulation solutions that allows you to dial in exact R-values for wall installations, helping you deliver a customized package that meets builders’ targets the first time, every time.

ProPink® Complete™ System