When Life Safety Matters Most

When Life Safety Matters Most

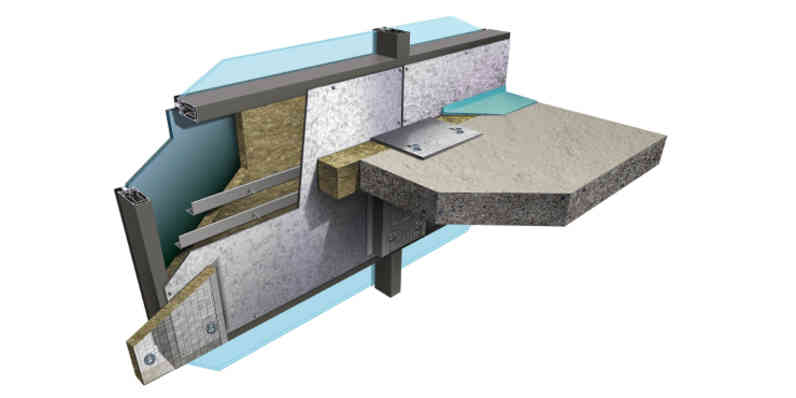

One of the most complex and least understood areas pertaining to where fire can spread is at the perimeter of a building, making perimeter fire containment systems critical. An understanding of fire containment is important for the safety of occupants in the building, as well as the safety of emergency responders. Even when lives are spared, fire losses can be devastating. A proper perimeter fire containment system helps save buildings, intellectual property and business capital, along with allowing the people inside the structure more time to escape in the event of a fire.