The pipes and equipment that process or carry water, steam, gas and petrochemicals must perform reliably under harsh industrial and environmental conditions that can lead to CUI. The insulating material and system is an important decision to mitigate CUI. The FOAMGLAS® Sealed System and FOAMGLAS® Spacer System are designed to help protect piping systems at risk for corrosion.

FOAMGLAS® Insulation Systems for Mitigating Corrosion Under Insulation

When designing process facilities, the selection of the insulation system is an important factor. Improper choices can not only lead to underperforming insulation systems, but also contribute to issues associated with corrosion under insulation (CUI).

Consequences associated with CUI can include:

- unanticipated failure of the process

- damage to equipment

- costly repairs

- downtime

- increased potential for leaks

- even fire hazards

Selection of the appropriate type of insulation for the system design is significant for mitigating CUI.

FOAMGLAS® Sealed System

FOAMGLAS® Sealed System

The FOAMGLAS® Sealed System utilizes the impermeability of cellular glass insulation and our new, proprietary joint sealant to help keep moisture out of the system.

Insulation joints are to be fully-sealed – from the exterior down to the pipe – using PITTSEAL® Hi-Temp LV RTV Sealant. This one-part, neutral cure sealant is formulated for use with FOAMGLAS® Insulation Systems, and does not contribute to corrosion.

The lower viscosity of the sealant enables efficient spreading and sealing. It cures to an elastomeric solid at room temperature. The sealant has a wide service temperature range from -238ºF to 450ºF (-150ºC to 232ºC).*

The system seals the joints and compartmentalizes the insulation system components to help limit the spread of corrosion.

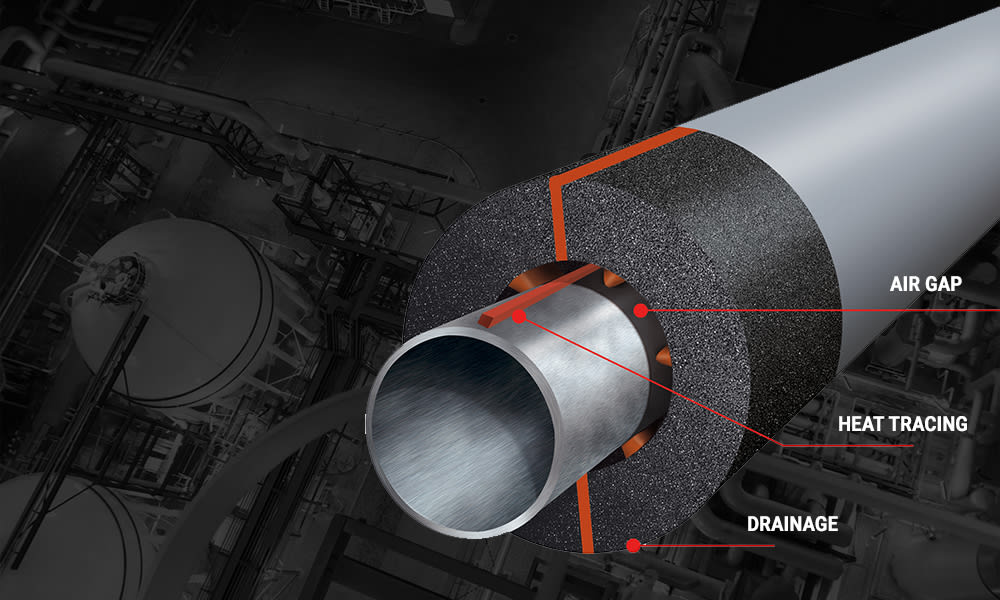

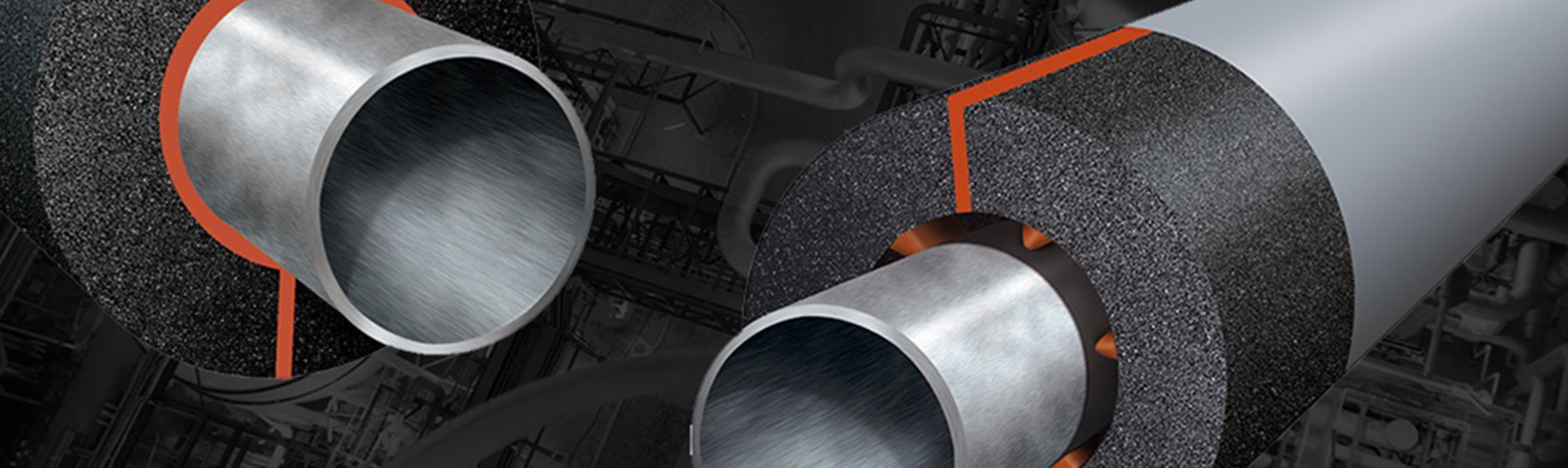

FOAMGLAS® Spacer System

FOAMGLAS® Spacer System

The FOAMGLAS® Spacer System utilizes proprietary spacer technology to create a 12mm (1/2 in.) air gap between the insulation and pipe. This can help to minimize the potential for water to remain in contact with the pipe. If the system is breached, its compartmentalized design helps promote channeling of moisture away from the pipe to points where it can be drained from the system.

Where to Specify:

Where CUI is a concern and:

- Where water intrusion is probable from secondary sources

- Above ambient and hot systems with continuous or near continuous

- operation

- Offshore or marine applications

- Acoustical consideration is needed

System Features and Benefits:

- Available for systems with continuous operating temperatures up to 200°C (392°F).

- Supports heat tracing configurations

- Compartmentalized and draining configurations

- Compatible sealants and adhesives

- Good acoustical properties*

Downloads

Downloads