Safer Fire Performance

99% Safer Fire Performance* No Added Fire Retardants

* 99% less smoke generation potential under controlled fire test conditions vs. a competitive combustible insulation material.

Test Methods:

Several test methods were used to assess fire performance in support of this claim. It should be noted that these test methods are not representative of all fire conditions and not claimed as such for the mentioned claim.

All testing was conducted at Intertek Building & construction. The NFPA 286 testing was conducted at their Elmendorf, Texas laboratory and the ASTM E662 testing was conducted at their Middleton, Wisconsin laboratory.

| Test Method | Test Name | Quantified Metric |

|---|---|---|

| NFPA 286 | Standard Methods of Fire Testing for Evaluating Contribution of Wall and Ceiling Interior Finish to Room Fire Growth | Smoke Volume |

| ASTM E662 | Standard Test Method for specific Optical Density of Smoke Generated by Solid Materials | Smoke Visibility |

Materials:

Two rounds of materials were used in this testing. Fiberglass unfaced insulation as well as a representative sample of Spray Foam (Open Cell and Closed Cell).

| Setpoint Label | Material Information | Material Type |

|---|---|---|

| SP1 | Open Cell Spray Foam-Gaco Quik Shield 108YM | SPF |

| SP2 | Closed Cell Spray Foam-Gaco OnePass | SPF |

| SP3 | Owens Corning EcoTouch R13 unfaced batt | SPF |

Results:

A. NFPA286: Standard Methods of Fire Tests for Evaluating Contribution of Wall and Ceiling Interior Finish to Room Fire Growth

Also known as the "room corner" test, NFPA 286, Standard Methods of Fire Tests for Evaluating Contribution of Wall and Ceiling Interior Finish to Room Fire Growth, provides a method of determining the flammability characteristics of exterior, non-load bearing wall assemblies and panels that are required to be of non-combustible construction but may contain combustible components.

| Open Cell SPF (SP1) | Closed Cell SPF(SP2) | Fiberglass (SP3) | |

|---|---|---|---|

| <strong>Smoke Volume (m2)</strong> | 433 | 117 | 11.2 |

| <strong>Peak Heat Release (kW)</strong> | 1016 | 609 | 322 |

- Open Cell SPF produced 38X (or 3700%) more smoke than unfaced fiberglass

- Closed Cell SPF produced 10X (or 900%) more smoke than unfaced fiberglass

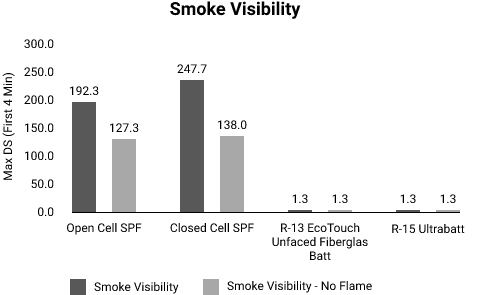

B. ASTM E662: Standard Test Method for Specific Optical Density of Smoke Generated by Solid Materials

Measurements are made of the attenuation of a light beam by smoke (suspended solid or liquid particles) accumulating within a closed chamber due to non-flaming pyrolytic decomposition and flaming combustion. Results are expressed in terms of specific optical density which is derived from a geometrical factor and the measured optical density, a measurement characteristic of the concentration of smoke. This standard measure and describes the response of materials, products, or assemblies to heat and flame under controlled conditions.

| Material | Maximum Ds With Flame (Average of 3) | Maximum Ds No Flame (Average of 3) | __ Times Less Visible Than FG or MW | __% Visibility Reduction from FG / MW |

|---|---|---|---|---|

| Open Cell SPF | 192.3 | 127.3 | 148X | 99.3% |

| Closed Cell SPF | 247.7 | 138 | 190X | 99.5% |

| Fiberglass Batt (UF) | 1.3 | 1.3 | - | - |

| Mineral Wool Batt | 1.3 | 1.3 | - | - |

- Open Cell SPF produced smoke over 140 times (or 14600%) more optically dense than unfaced fiberglass (produced smoke 140 times harder to see through than unfaced fiberglass)

- Closed Cell SPF produced smoke over 180 times (or 18900%) more optically dense than unfaced fiberglass (produced smoke 180 times harder to see through than unfaced fiberglass)