SE4849

FASTER LINE SPEEDS AND HIGHER GLASS LOADINGS

Specifications and Literature

Performance Attributes

Superior Composite Strength

Superior Glass Dispersion and Increased Part Strength

Enhanced Service Life

- Improved Manufacturing EconomicsGreater than 50% reduction in fuzz generation relative to competitive reinforcements for easier processing and less downtime for clean-up.

- Superior Composite StrengthIncreased splice tensile strength improves package to package transfer efficiency.

Increased lubricity imparts lower strand tension enabling up to a 40% increase in compounding line speed for

reduced manufacturing costs. - Superior Glass Dispersion and Increased Part StrengthOutstanding compatibility with Polyolefins, enabling better wet-out, uniform glass dispersion and potentially higher glass loading.

Optimized adhesion to the polymer matrix offering excellent mechanical properties to meet stringent end-use requirements. - Enhanced Service LifeAdvantex® glass helps fight corrosion, enhancing service life compared to standard E-glass.

- ApplicationsSE4849 product is designed for use in LFT-G (pellets) Polyolefin (primarily PP) hot-melt compounding processes for the manufacturing of structural and semi-structural automotive applications including front-end modules, seat carriers and door modules, as well as a variety of consumer goods, appliances and power tools. SE4849 is also optimized for used in CFRT (Continuous Fiber Reinforced Plastic) tapes for structural applications where the performance characteristics of a continuous unidirectional glass reinforcement can significantly improve end-use performance.

Technical Information

Availability (Standard Reference) & Technical Characteristics (Nominal Values)

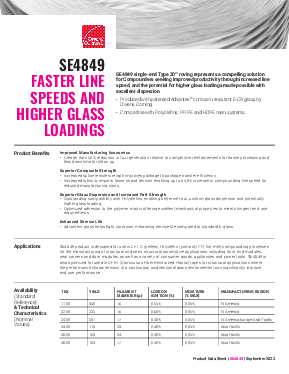

| TEX | YIELD | FILAMENT DIAMETER (μ) | LOSS ON IGNITION (%) | MOISTURE (% MAX) | MANUFACTURING REGION |

|---|---|---|---|---|---|

| 2400 | 207 | 17 | 0.40% | 0.05% | N. America; Europe; Asia Pacific |

| 4400 | 113 | 23 | 0.40% | 0.05% | Asia Pacific |

| 4800 | 103 | 24 | 0.40% | 0.05% | Asia Pacific |

| 4800 | 103 | 17 | 0.40% | 0.05% | Asia Pacific |

Packaging & Palletization (Standard Reference)

PALLET DIMENSIONS

| PACKAGING | PALLET HEIGHT (CM) | PALLET LENGTH (CM) | PALLET WIDTH (CM) | PALLET WEIGHT (NET, KG) | PACKAGES PER PALLET | NUMBER OF LAYERS |

|---|---|---|---|---|---|---|

| No Tube | ~125 | 115 | 115 | ~1200 | 64 | 4 |

| No Tube | ~97 | 115 | 115 | ~900 | 48 | 3 |

| Thicker Tube | ~200 | 115 | 115 | ~900 | 48 | 3 |

Package size will vary by region.

Labeling

Each individual package is labeled with information including: product name, tex/yield, producing plant and production date.

Storage

Unless otherwise specified, it is recommended to store glass fiber products in a cool, dry area. The glass fiber products must remain in their original packaging material until the point of usage. The product should be stored in the workshop in its original packaging for 48 hours prior to its utilization, to allow it to reach the workshop temperature condition and prevent condensation, especially during the cold season. The packaging is not waterproof. Be sure to protect the product from the weather and other sources of water. When stored properly, there is no known shelf life to the product, but retesting is advised after three years from the initial production date to insure optimum performance.

Regional Availability

Applications

- Consumer Goods > Appliance

- Consumer Goods > Electronics

- Consumer Goods > Sports and Leisure

- Pipes and Tanks

- Transportation > Automotive > Exterior > (Body) Panels

- Transportation > Automotive > Exterior > Surface Aspect

- Transportation > Automotive > Interior > Long fiber (LFRP)

- Transportation > Automotive > Interior > PA Applications

- Transportation > Automotive > Interior > Semi-Structural

- Transportation > Automotive > Interior > Structural

- Transportation > Automotive > Interior > TP (CFRT) Tapes

- Transportation > Heavy Transportation

Talk To An Expert

We know your business is important - which is why we have hand selected team members with knowledge specific to your needs. For immediate assistance, reach out to our experts below and we'll be in touch with you.

Contact Us

Even though we’re a global company, we’re always ready to answer your questions. Call to speak with an Owens Corning representative.

1-800-GET-PINK®