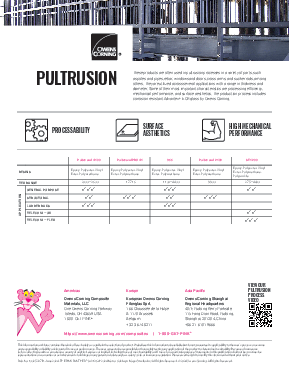

Applications

PulStrand® 2100 is designed for pultrusion applications in polyester, vinyl ester, polyurethane, and epoxy resin systems, using conventional dip bath or resin injection technology, to manufacture poles, cross arms, and other large structural profiles.