PipeStrand® S4000 HP2

MORE MODULUS HIGH PERFORMANCEMORE MODULUS HIGH PERFORMANCE

Specifications and Literature

Performance Attributes

Excellent Processability

Reliable Supply

- Proven Performance• Fiber Modulus: 91GPa – true performance proven by sonic modulus of glass fiber (NOL TR 65-87) testing method.

- Excellent Processability• High unwinding performances to allow fast filament winding process.

• Fast wet-out in epoxy resin, allowing up to 80% fiber volume fraction. - Reliable Supply• Owens Corning® H2 Glass is continuously produced at scale and increasing capacity, delivering reliable product supply and consistency.

- APPLICATIONSPipeStrand® S4000 HP2 is designed for the manufacturing of lighter weight glassfiber reinforced composite pressure vessels. PipeStrand® S4000 HP2 improves material systems for Type IV vessel filament winding.

Technical Information

Properties

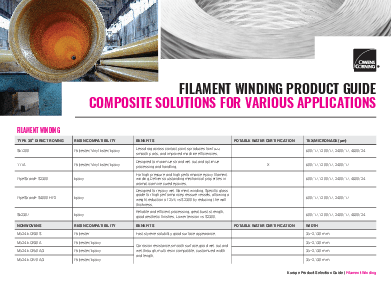

| Product | Nominal Filament Diameter (microns) | LINEAR DENSITY (TEX) ISO 1889 | SOLIDS (%) ISO 1887 | MOISTURE (%) ISO 3344 |

|---|---|---|---|---|

| PipeStrand® S4000 HP2 | 17 | 600/1,200/2,400 | 0.55 +/- 0.12 | <= 0.1 |

Availability and Packaging

This product is available globally. Type 30® single-end roving is available in a single-end internal-pull package. Each pallet weighs approximately 1 metric ton. Pallets are stretch-wrapped for load stability. All doffs are wrapped with Tack-Pak™ for protection and to aid package run-out and transfer. Full doffs are approximately 19 kg (40 lbs) and can be packaged in bulk or Creel-Pak® format.

Standard package

- Cylindrical doff without tube, outside diameter (OD) +/- 270 mm, height 260–300 mm

- Partial doffs have small diameters.

- Max doff weight must not exceed 19kg (40 lbs)

- Doff covered by a Tack-Pak™ film.

Pallet

- Size: 1150 x 1150 mm, 4 ways entry

- 16 doffs (max OD) per layer

- Pallets are 3 or 4 tiers high

- Pallet is stretched-wrapped

Labeling

Each individual doff is labeled with information including: product name, Tex/yield, producing plant, and production date and weight. Each of the four pallets is labeled on one side.

Storage

Glass fiber products must remain in the packaging material until just prior to use. It is recommended to bring material into a workshop area at least 24 hours prior to use. PipeStrand® S4000 HP2 roving should be stored in a dry area with ambient temperature optimally from 8°C to 26°C and relative humidity of 70% or less. To ensure optimal performance, retesting is recommended for products stored more than two years from the initial production. The packaging system is designed to allow stacking of two pallets. When stacking two high, care should be taken to place the top pallet correctly and smoothly.

Regional Availability

Applications

- Pipes and Tanks

Talk To An Expert

We know your business is important - which is why we have hand selected team members with knowledge specific to your needs. For immediate assistance, reach out to our experts below and we'll be in touch with you.

Contact Us

Even though we’re a global company, we’re always ready to answer your questions. Call to speak with an Owens Corning representative.

1-800-GET-PINK®