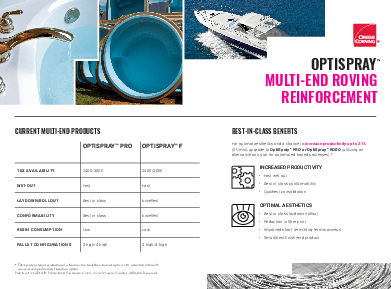

OptiSpray® PRO Roving

FOR OPTIMAL PRODUCTIVITY AND AESTHETICSSpecifications and Literature

Performance Attributes

REDUCED COST

IMPROVED AESTHETICS

SMART PACKAGING

- INCREASED PRODUCTIVITY• Productivity gains (ft²/min) of up to 21% on complex geometries have been realized during the open-mold manufacturing process, versus the lowest-performing fiberglass alternative.*

• OptiSpray® PRO roving is offered in a unique 4-high doff pallet configuration weighing ~2700 lb (1254 kg) per pallet. This design increases productivity by requiring less pallet turnovers and less time moving material by fewer employees.

* Third-party external evaluation of a Marine structural liner showed up to a 21% reduction in time/ft² versus worst-performing fiberglass option. - REDUCED COST• Higher glass loading with optimal resin consumption reduces the amount of expensive resin required.

- IMPROVED AESTHETICS• Reduction in fiber print, improved short-term and long-term waviness, and improved B-side cosmetics.

- FAST WET-OUT• Designed to provide optimal performance for spray-up applications where fast wet-out speed is preferred; great performance in various types of part complexities.

- Packaging to Reduce Waste and Increase Floorspace• The optional 4-high pallet design increases the amount of fiberglass material in the standard pallet footprint by 33%, enabling producers to fit more pounds within a distribution center, on a truck during delivery, and in the manufacturing site with no impact to floor space.

Resources

Technical Information

Technical Characteristics (Nominal Values)

| Linear Weight Of Roving (Tex) | Yield (yds/lb) | Loss On Ignition (%) Iso 1887: 1995 |

|---|---|---|

| 2400 | 207 | 1.25 |

| 3000 | 165 | 1.25 |

Availability and Packaging (Standard Reference)

Each OptiSpray® PRO doff is protected by a tack-wrap polythene film and identified by an individual label; please do not remove film during use.

Creel-Pak™ and customer specific packaging may be available upon request.

| Product | Doff Ø (MM) | Pallet Dimensions L X W (CM) |

Layers per Pallet | Doffs per Layer | Total Number of Doffs | Creel-Pak™ | Pallets |

|---|---|---|---|---|---|---|---|

| Number of Ends | Net Weight* (KG) | ||||||

| OptiSpray® PRO Rov. Creel Pak™ 4E 2400/3000 |

277 | 114 x 114 | 3 | 16 | 48 | 4 | 941 |

| OptiSpray® PRO Rov. Creel Pak™ 2E 2400/3000 |

277 | 114 x 114 | 3 4 |

16 | 48 64 |

2 | 941 1254 |

| OptiSpray® PRO Rov. Close Top™ 2400 |

303 | 38 x 51 in 96.5 x 129.5 cm |

4 | 12 | 48 | Individual Boxes | 1104 |

Labeling

Each doff has a self-adhesive identification label, showing the product reference and the production date.

Each pallet has two identification labels detailing the product reference, pallet net and gross weights, production date and pallet production code.

Storage

It is recommended to store glass fiber products in a cool, dry area. The glass fiber products must remain in their original packaging material until the point of usage; the product should be stored in the workshop, within its original packaging, 48 hours prior to its utilization, to allow it to reach the workshop temperature condition and prevent condensation, especially during the cold season. The packaging is not waterproof. Be sure to protect the product from the weather and other sources of water. When stored properly, there is no known shelf life to the product, but retesting is advised after two years from the initial production date to ensure optimum performance.

Regional Availability

Applications

- Consumer Goods

- Transportation > Automotive > Exterior > (Body) Panels

- Transportation > Automotive > Exterior > Surface Aspect

Talk To An Expert

We know your business is important - which is why we have hand selected team members with knowledge specific to your needs. For immediate assistance, reach out to our experts below and we'll be in touch with you.

Contact Us

Even though we’re a global company, we’re always ready to answer your questions. Call to speak with an Owens Corning representative.

1-800-GET-PINK®