APPLICATIONS

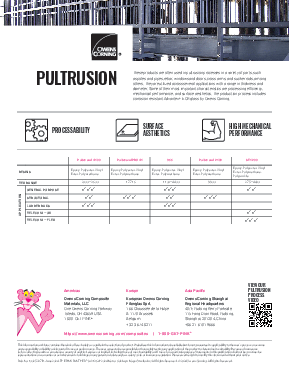

111A is designed for versatility in several processes such as knitted or woven fabrics, inputs for multiaxial fabrics, filament winding, and pultrusion. Industries include building and construction, power generation, and consumer durable goods.